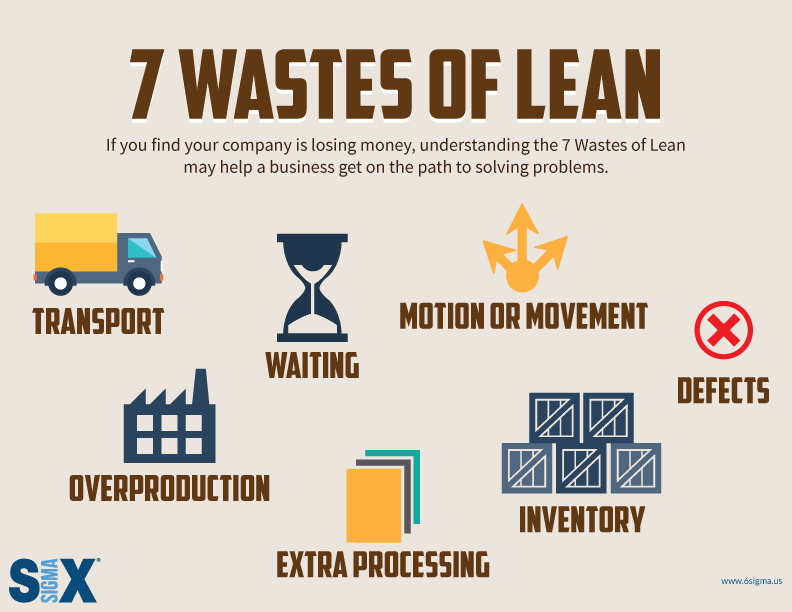

Infographic: Understanding the 7 Wastes of Lean

Every time you eliminate waste in the day-to-day process to manufacture your product, it increases your profit. It is that simple! The 7 wastes of Lean, listed below, are the main culprits.

Transport: Moving products or materials from one location to another adds cost, doesn’t add value, and wastes time.

Inventory: Unnecessary inventory of raw materials that collects before or after a process. Takes up space, unnecessary expenditure.

Waiting: This is idle time that wastes money waiting for materials or information, or further instruction.

Overproduction: This is making more product than needed, assuming that the customers will need it. Anything made beyond what is needed is a waste of resources, time and space.

Motion or Movement: This is in regards to excess movement or motion because of poorly designed workspace in the organization.

Defects: The causes can range from poor quality control to failure to communicate and everything in between.

Extra Processing: This is anything extra that you include after the product has met specifications, such as extra wrapping/boxes, just about anything that is not needed.

For more information on our Lean Six Sigma courses and services, please visit 6sigma.us.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs